Who says technology and food waste avoidance don’t mix? That combination works quite well–just ask LeanPath.

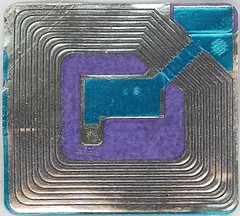

Which brings us to RFID tags, a microchip with an antenna that transmits information wirelessly to a reader. These tags are are now being used in Europe to track pallets’ progress through the “cool chain.” A Dutch company, a German retailer and a Spanish strawberry grower have teamed up to track the berries temperature on their continental journey.

The RFID tags measure the temperature of each pallet every 15 minutes of the journey and, upon arrival at its destination, wirelessly transmit the info to a computer.

The RFID tags measure the temperature of each pallet every 15 minutes of the journey and, upon arrival at its destination, wirelessly transmit the info to a computer.

From that point, a program calculates the remaining shelf life of the fruit. That info allows retailers to determine which strawberries are ripest and should be put on display first.

Eelco de Jong, Director of Marketing and Business Development at Ambient Systems (the Dutch company): “It is great to be able to contribute to a reduction in the loss of wasted food.”

While the article doesn’t discuss it, I’m hoping that this advance could lead to smarter expiration dates based on how the product has been handled, not a cautious best guess. That would mean stamping or printing a date on packages at the store, but how hard could that be?

— —

— — compostables bin in the food court for everything from customers’ food to their plates and utensils.

compostables bin in the food court for everything from customers’ food to their plates and utensils. I love the idea, since it focuses on when the food actually isn’t fit for eating, not a comically cautious “best-before” date or an ambiguous “sell-by” date. Of course, the discussion now would be around what “unsafe to eat” means.

I love the idea, since it focuses on when the food actually isn’t fit for eating, not a comically cautious “best-before” date or an ambiguous “sell-by” date. Of course, the discussion now would be around what “unsafe to eat” means. — —

— — A16 mostly uses prosciutto scraps saved throughout the week. No wonder they’re so good!Â

A16 mostly uses prosciutto scraps saved throughout the week. No wonder they’re so good!  this is this the case at all Olive Gardens.

this is this the case at all Olive Gardens.

Does anyone do this at your farmer’s market? If so, I’d love to hear how it works. If not, the opportunity is ripe for you to

Does anyone do this at your farmer’s market? If so, I’d love to hear how it works. If not, the opportunity is ripe for you to  rise during Ramadan. The Turkish Foundation for Waste Reduction (TIVSA) noted that…

rise during Ramadan. The Turkish Foundation for Waste Reduction (TIVSA)Â noted that…